Pressure tanks store and supply water to your house under pressure with the help of compressed air. When the water pressure in the tank falls below the cut-in pressure, the pressure switch activates the pump until water pressure in the tank increases to the cut-off pressure.

Here is a brief guide of how a pressure tank works:

- Water Inflow: When water is pumped into the pressure tank from the well or water source, the tank initially contains a volume of air above the water.

- Air Cushion: This air cushion acts as a compressible buffer between the water and the tank itself. It exerts pressure on the water and helps maintain a consistent pressure level throughout the plumbing system.

- Pump Activation: When a faucet or appliance is turned on, the pressure in the water pipes drops. This drop in pressure triggers the well pump or water system pump to turn on.

- Water Discharge: The pump draws water from the pressure tank and pushes it into the plumbing system, delivering it to the faucets, showerheads, and appliances.

- Pressure Maintenance: As the water is drawn from the tank, the air cushion inside the tank continues to exert pressure on the water, keeping the water pressure consistent even when the pump is not running.

- Pump Deactivation: Once the desired pressure level is reached, the pump turns off. The pressure tank continues to supply water to the plumbing system from its stored water and maintains pressure.

- Cycling On and Off: The pressure tank and pump cycle on and off as water is used and the pressure in the system fluctuates. This prevents the pump from constantly turning on and off with every faucet use, reducing wear and energy consumption.

- Recharging the Air Cushion: Over time, the air cushion in the pressure tank may become depleted. To maintain optimal performance, the air cushion needs periodic maintenance, which involves checking and adjusting the air pressure using a pressure gauge and a bicycle pump or compressor.

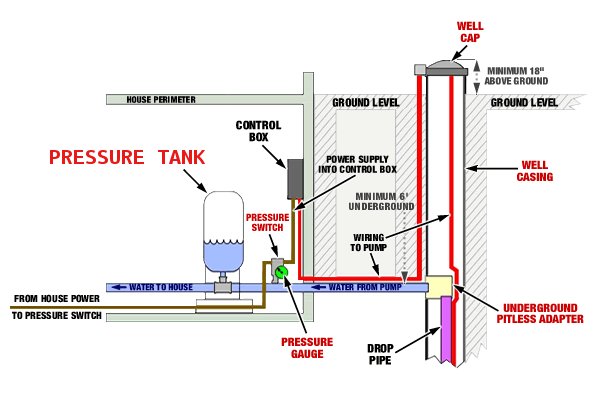

Water Pressure Tank Installation Diagram

The image below shows the typical installation diagram of a well pressure tank, as well as other components of a well system.

How a Bladder Pressure Tank Works

A bladder pressure tank is a steel tank with a bladder inside which looks like a balloon. The bladder occupies the lower section of the tank while the top part is filled with compressed air. An air inlet valve at the top of the tank allows you add pressure the tank.

The pressure tank is connected to a pressure switch, pump, and a check valve. The system is powered by electrical power with a dedicated circuit breaker.

A well pump is responsible for pumping water from the well to the pressure tank, while a check (which is usually installed on the water pipe before the pressure tank) prevents water from flowing back, or out of the pressure tank to the well.

The pressure switch is used to automatically switch the pump on and off. It has 2 pressure settings. The first pressure setting is called the cut-in pressure while the second pressure is called the cut-out pressure.

The cut-in pressure is the water pressure which when reached by the water in the pressure tank, the pressure switch triggers the pump to cut in On the other hand, the cut-out pressure is the pressure of the water in pressure tank when the pressure switch turns the pump off.

If for instance the pressure switch’s rating is 40-60 psi, the cut-in pressure is 40 psi while 60 psi is the cut-out pressure. The cut-in pressure and the cut-out pressure can however be adjusted, as long as the maximum cut-out pressure is not exceeded.

The pressure tank is usually filled with air whose pressure should be about 2 psi lower than the cut-in pressure of the pressure switch. If for instance the cut-in pressure is 40 psi, the air pressure in the pressure tank should be 38 psi.

The pressure tank prevents the well pump from running continuously. Without the pressure tank, the well pump would kick in every time someone washes their hands on the sink or even flushes the toilet, to compensate for the lost water in the pipes.

Let us look at a typical cycle of how the pressure tank, pressure switch and the well pump works together.

- After work, you are so tired and need to soak up in the tub to relax. You therefore fill the tub with hot water.

- The hot water empties the water heater which in return draws water from the well pressure tank.

- When the water pressure in the pressure tanks falls below the cut-in pressure, the pressure switch triggers the pump which starts to fill the pressure tank with more water.

- When the water pressure in the tank reaches the cut-out pressure, the pressure switch turns the pump off.

- The check valve prevents the water from flowing out of the pressure tank and back to the well.

If there is a high water demand in your house (usually in the morning and evening), the well pump will turn on and off constantly to keep up with the demand. During the day when nobody is around the well pump will be off almost all day.

Due to the elastic nature of the bladder, it is able to increase in volume as more water is being pumped in. The more the bladder inflates the more it compresses the air in the upper chamber which in return creates high water pressure. High water pressure translates to more water.

Do not exceed the pressure rating of the pressure tank though. Doing that will cause the bladder to rupture. When that happens, you will need to replace the pressure tank, as it will be waterlogged.

How Do I Know if My Pressure Tank is Bad?

For someone using water from a well, low water pressure is the first sign of a bad pressure tank. The other sign is when the well pump is running constantly or nonstop. This is in most cases caused by a waterlogged pressure tank. A faulty pressure switch can also be the reason.

If you want to check the integrity of your well pressure tank, this is the process to follow:

- Turn off power to the pressure switch at the circuit breaker. This will prevent the pressure switch from turning on the pump when the water pressure in the tank falls below the cut-in pressure.

- Turn off the shut off valve. Most well water systems have a shut off valve between the pressure tank and the house. This will prevent air from entering the house water pipes creating an air lock. If you have no valve, open the nearest faucet.

- Connect a garden hose to the pressure tank’s drain valve bib at the bottom of the tank. Direct the end of the hose out to the yard or a floor drain.

- Turn on the drain valve and let the pressure tank drain out completely. Once fully drained, turn off the drain valve and remove the garden hose.

- Hold the top of the pressure tank and try to tip or push it away. If the pressure tank is waterlogged (bladder is raptured), it will simply be too heavy and won’t move. A good pressure tank will tip off easily since air has no significant weight.

Another thing you can do is to bang or strike the pressure tank with a metal rod from top to bottom after draining it. If it is waterlogged, it will sound really solid but if it is ok it will sound hollow.

You can as well check the pressure of the air in the pressure tank if there are no signs of waterlogging. If the air pressure is too low, you will have low water pressure in your house.

Connect a pressure gauge to the air inlet valve at the top of the pressure tank. The inlet valve is usually covered with a cap so you will first need to remove it.

If the pressure is way too low compared to the cut-in pressure of the pressure switch, you definitely need to pump in more air.

Is the Pressure Switch Faulty?

Sometimes You may not be dealing with a bad pressure tank but a faulty pressure switch. How can you tell if your pressure switch is faulty?

A bad pressure switch will not trigger the well pump to kick in when the water pressure in the pressure tank falls below the cut-in pressure, or it will fail to stop the pump when the water pressure exceeds the cut-out pressure.

Pressure tanks are usually designed with a relief valve. This valve will open if the pressure switch fails to turn off the pump, preventing the tank from bursting. The bladder will however rupture.

If you ever find water pooling around the pressure tank and the pump is still running, you have a faulty pressure switch. A bad pressure switch will need to be replaced.

If you need to adjust the water pressure in your pressure tank, you will need to adjust the cut-in and cut-out pressure at the pressure switch.

- Start by turning off power to the pressure switch. Operating the pressure switch with live power can lead to electrical shock.

- Remove the pressure switch cover. The cover is attached to the switch using a screw.

- Once the cover is out, you will see 2 springs compressed on bolts using nuts. Each of the springs control the cut-in and cut-out pressure depending on how much they are compressed.

- Use an adjustable wrench to loosen or tighten the nuts to get your desired cut-in and cut-out pressures. You will need to keep turning the power on and off as you adjust the pressure until you are satisfied with the figures on the pressure gauge. To get the exact cut-in and cut-out pressure you will need to drain the tank and watch when it kicks in and out.

- Don’t forget to adjust the air pressure in the pressure tank to just under 2 psi of the new cut-in pressure.

Apart from bladder pressure tanks, there are 2 other types of well pressure tank. These are air-over-water pressure tanks and diaphragm pressure tanks.

In air-over-water pressure tanks, there is no boundary between the compressed air and water. With time the air gets dissolved in the water and will thus need to be recharged from time to time.

Diaphragm water tanks contains a rubber diaphragm that separates the compressed air and the water. As more water flows in, the diaphragm curves upwards compressing the air further and increasing the water pressure.

As mentioned earlier, bladder pressure tanks are the most modern and the best well pressure tanks to buy.