I was writing an article about the different types of thread sealants and I remembered that all threads are not created equal. Pipe thread forms in the United States is different to that of the United Kingdom.

The two main types of pipe thread styles are National Pipe Thread (NPT) and British Standard Pipe (BSP). So, what is the difference between NPT and BSP?

Actually, the difference in NPT and BSP is not in how much one form of thread is better than the other or how one is used but rather where each form of thread is used. NPT threads are used in the United States and Canada while BSP threads are used in United Kingdom and many countries in Europe, Asia and Africa.

But what is the main difference between NPT and BSP threads? How can you tell them apart?

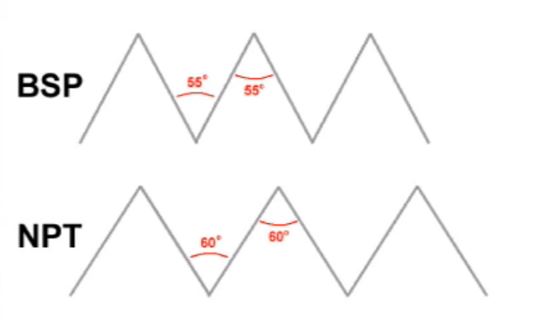

The main difference between NPT and BSP threads is that the thread angle in NPT threads is 60 degrees while that of BSP pipes is 55 degrees. NPT threads are also pointed at the crests and roots whereas BSP’s are rounded.

Can You Use BSP with NPT?

One question I’ve always been asked when talking about these two forms of threads is “Can you connect a fitting with BSP threads to a pipe with NPT threads provided they are of the same size”?

NPT and BSP pipes are incompatible. NPT threads’ crests and roots are pointed compared to BSP’s rounded ones. Also, the thread angle in NPT is 600 unlike BSP’s 550 meaning the 2 threads have dissimilar pitches. Connecting them together will therefore result in thread misalignment, damage and leaks.

In sensitive services like the oil and gas industry where pressure of the hydrocarbons can reach 15000 pounds per square inch (psi), a leaking pipe connection can be catastrophic. That is the mean reason BSP and NPT threads shouldn’t be used together.

If you however want to connect a BSP pipe to an NPT pipe or fitting, there are adapters in the market for that purpose. There are different types of adapters:

- NPT female to BSP male

- BSP female to NPT male

- NPT female to BSP female

- BSP female to NPT female (same as above)

How Do You know if a Thread is BSP or NPT?

As I have already mentioned, BSP and NPT threads have different thread angles and therefore different pitches. That however is still not easy to tell them apart especially when you are dealing with small ½-inch pipes or fittings.

To tell if a thread is BSP or NPT, check if there is a taper. BSP threads are usually straight/parallel while NPT threads are usually tapered. If the threads are the same size then it is BSP whereas if the first thread is small (in diameter) that the last then it is NPT.

It is for this very reason that NPT threads are also known as National Thread Taper. They are also known as American threads while BSP threads are known as British threads.

BSP vs NPT threads

Let us now look at the differences between BSP and NPT threads in a table summary.

| Aspect | NPT (National Pipe Taper) | BSP (British Standard Pipe) |

|---|---|---|

| Terminology | Commonly known as NPT threads. | Also referred to as BSP threads. |

| Origin | Developed in the United States, predominantly used in North America. | Originated in the United Kingdom and is commonly used in Europe and various regions worldwide. |

| Thread Angle | 60 degrees | 55 degrees |

| Thread Shape | Tapered (conical) | Tapered (conical) |

| Thread Direction | Right-hand | Right-hand |

| Sealing Mechanism | Relies on a thread interference fit for sealing. Typically uses Teflon tape (PTFE tape) or pipe dope to achieve a leak-proof joint. | Relies on a thread interference fit for sealing. Typically uses a sealing compound or tape to achieve a leak-proof joint. |

| Compatibility | NPT threads are not compatible with BSP threads due to differences in thread angle and sealing mechanisms. | BSP threads are not compatible with NPT threads due to differences in thread angle and sealing mechanisms. |

| Use Cases | Commonly used in plumbing, HVAC, and industrial applications throughout the United States and North America. | Widely used in plumbing, automotive, pneumatic systems, and industrial applications in Europe and various parts of the world. |

| Standard Sizes | Available in various sizes, including fractional and nominal sizes. | Available in various sizes, including metric and imperial measurements. |

| Common Applications | Found in residential and commercial plumbing, water and gas systems, and industrial equipment. | Commonly used in various industries, including automotive, hydraulic systems, and industrial machinery. |

| Standards | Conforms to ANSI/ASME B1.20.1 and ASTM standards. | Conforms to BS 21 and ISO 7 standards. |

NPT vs BSP Chart

| Nominal Size | Thread Density (per inch) NPT | Thread Density BSP) | Pitch (Inches) NPT | Pitch (mm) BSP |

|---|---|---|---|---|

| 1/16 | 27 | 28 | 0.03703704 | 0.907 |

| 1/8 | 27 | 28 | 0.03703704 | 0.907 |

| 1/4 | 18 | 19 | 0.05555555 | 1.337 |

| 3/8 | 18 | 19 | 0.05555555 | 1.337 |

| 1/2 | 14 | 14 | 0.07142857 | 1.814 |

| 3/4 | 14 | 14 | 0.07142857 | 1.814 |

| 1 | 11 1/2 | 11 | 0.08695652 | 2.309 |

| 1 1/4 | 11 1/2 | 11 | 0.08695652 | 2.309 |

| 1 1/2 | 11 1/2 | 11 | 0.08695652 | 2.309 |

| 2 | 11 1/2 | 11 | 0.08695652 | 2.309 |

| 2 1/2 | 8 | 11 | 0.12500000 | 2.309 |

| 3 | 8 | 11 | 0.12500000 | 2.309 |

| 3 1/2 | 8 | 11 | 0.12500000 | 2.309 |

| 4 | 8 | 11 | 0.12500000 | 2.309 |

National Pipe Threads (NPT) vs National Pipe Straight (NPS)

Apart from NPT, there are other forms of threads used in the United States that can confuse you if you don’t know the differences between them. National Pipe Straight (NPS) is one form.

The difference between National Pipe Thread (NPT) and National Pipe Straight (NPS) is that NPT threads are tapered while NPS threads are straight/parallel. They however have the same thread angle, shape and pitch.

As such you can therefore imagine how hard it is to differentiate between NPS and BPS seeing that both have parallel threads. Although they both have different thread angle and pitch, it is not easy telling them apart

Tapered threads provide a better seal when screwing the male connection into the female connection since maximum pressure is applied on the threads. With these types of threads, you will need a thread sealant like Teflon tape or pipe dope.

When it comes to parallel threads like NPS, a gasket or rubber O-ring will be required to create a tight seal. The two male and female connections squeeze the rubber O-ring/gasket until it deforms to create the seal.

While NPT and NPS threads will easily engage, they do not form a good seal and should therefore not be used together. There will be gaps between the threads which will result in leaks.

NPT vs NPTF

National Pipe Taper Fuel is similar to NPT in almost every way. The difference between the 2 is that NPTF is designed to provide a better and leak-free connection without the use of a thread sealant.

NPTF threads have the same thread degree, pitch, taper, shape and length of threads but their crest and root are adjusted for an interference fit, which eliminates the spiral leaking path.

BSP vs BSPT

The difference between British Standard Pipe (BSP) and British Standard Pipe Taper (BSPT) is that BSP threads are parallel while BSPT threads are tapered. The thread angle, pitch and shape is however the same.

Again, it means that telling BSPT and NPT threads apart will also not be easy unless you keenly check the thread angle or how sharp or rounded the crests and roots are.

Just as is the case with NPS, you will need a rubber washer/O-ring/gasket to create a seal when connecting male and female connections with BSP threads. On the other hand, a thread sealant like Teflon tape will be needed to seal BSPT connections.

In a bid to differentiate the 2 threads, BSP threads are commonly known as BSPP. The second “P” simply denotes that the threads are parallel, the same way the “T” in BSPT denotes that the threads are tapered.

Note: If you decide to use Teflon tape instead of pipe dope, make sure that you wrap it in a clockwise direction. Otherwise it will unravel when screwing in the male connection resulting in leaks. Check out this post for more details.